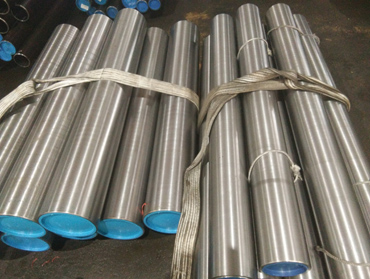

API 5L PSL1 X56 line pipe

The company can supply seamless type and welded type of API 5L PSL1 X56 line pipe. There are many manufacturing process like seamless(SMLS), electric resistance welding (ERW), high frequency welding (HFW), low frequency welding (LFW), and submerged arc welding (SAW). Welcome to contact us if you’re interested in our API 5L PSL1 X56 line pipes.

Introduction

API 5L PSL1 X56 line pipe size

Standard |

Specification for Line Pipe(ANSI/API specification 5L - 44th Edition, October 1, 2007) |

Line pipe sizes |

Nominal Pipe Size 1/2" to 48 " O.D. |

Wall thickness |

SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XS, SCH XXS, All API 5L X56 Pipe Thickness available |

Pipe ends |

Plain, Bevel, Screwed, Threaded l245 pipe |

Manufacturing types |

Seamless / ERW / Welded / Fabricated / CDW |

Application & uses |

Conveying gas, water, oil, and other liquids |

The technical data of API 5L PSL1 X56 line pipe

It is given based on API Spec 5L-2007 version. Below are the chemical composition and mechanical properties of seamless type API 5L PSL1 line pipe.

Chemical composition(a, %) of API 5L PSL1 X56 seamless pipe

C max. |

Mn max. |

P max. |

S max. |

V max. |

Nb max. |

Ti max. |

0.28 |

1.40 |

0.030 |

0.030 |

d |

d |

d |

c, Unless otherwise agreed,Nb+V≤0.06;

d, Nb+V+Ti≤0.15;

Mechanical properties of of API 5L PSL1 X56 seamless pipe

Pipe grade |

Yield Strength, Rt0.5 Min (MPa) |

Tensile Strength, Rm Min (MPa) |

L390 or X56 |

390 |

490 |

API 5L PSL1 X56 seamless pipe acceptable delivery condition

API 5L PSL1 line pipes can be delivered in as-rolled, normalizing rolled, thermomechanical rolled, thermomechanical formed, normalizing formed, normalized, normalized and tempered, or quenched and tempered.

Available pipe tests for API 5L PSL1 line pipe

Chemical composition analysis(product analysis)

Tensile tests

Hydro-static test

Bend test

Flattening test

CVN impact test for PSL2 line pipe

MT magnetic particle testing

NDT non-destructive testing

API 5L PSL1 X56 line pipe is a hot selling steel pipe product. It is used for the transportation of gas, water and oil. Pipeline steel coated line pipes are resistant to crack propagation.

Application

Our Teams

We Can Supply

-

Steel Plates

-

Steel Pipes

-

Steel Coils

-

Alloy Steels

-

Stainless Steel

-

Profile Steels

Why Choos Us?

1. We have our own factory, complete quality management system, and can provide customized services.

2. Fifteen years of steel export experience, with own agents in Bangladesh, Turkey, Cameroon and other countries;

3. Product quality is guaranteed, and the ship plates are certified by nine major classification societies. Various testing and services can be provided, and third-party testing is accepted;

4. Professional after-sales service team to provide various services to our customers.

Get Price And Support

Simply complete the form below, click submit, you will get the price list and our representative will contact you within one business day. Please also feel free to contact us by email or phone. ( * Denotes a required field).