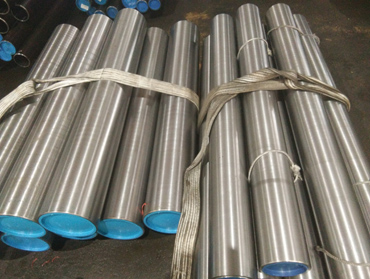

ERW Steel Pipe

ERW pipe (Electric Resistance Welded pipe) is manufactured by cold forming a flat steel strip into a rounded tube by passing it through a series of forming rollers to obtain a longitudinal seam. The two edges are then simultaneously heated with a high frequency current and squeezed together to produce a bond. The longitudinal ERW seam does not require filler metal while impurities in the heat affected zone are extruded during the welding process.

Introduction

Typical pipe material

Standard

|

Common grades |

ASTM A53 |

AA53 GR.A, A53 GR.B |

GB/T 1591 |

10#, Q195, Q235B, Q345B, Q345D |

ASTM A252 |

A252 Gr.2 , A252 Gr.3 |

JIS G3444 |

JIS STK400, STK500 |

API 5L |

Gr.B, X42, X46, X52, X56, X60, X65, X70, X80 |

EN 10219 |

S235JRH,S275J0H,S275J2H,S355J0H,S355J2H, S355K2H |

ERW Pipes Specification

Out diameter: 17.1mm--660mm

Wall thickness: 0.6-25.4mm

Length: 3meter-18meter

Manufacturing type: ERW (Electric Resistance Welded) Steel Pipe,HFW (High-Frequency Welding) Steel Pipe

Uses: Welded steel pipes for use in pipeline transportation system in the petroleum and natural gas (oil & gas) industries, water pipeline, structural & construction.

Application

Our Teams

We Can Supply

-

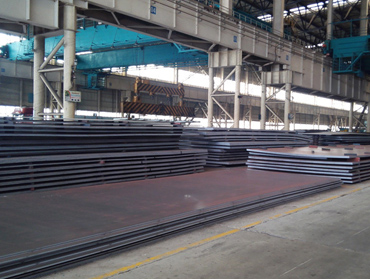

Steel Plates

-

Steel Pipes

-

Steel Coils

-

Alloy Steels

-

Stainless Steel

-

Profile Steels

Why Choos Us?

1. We have our own factory, complete quality management system, and can provide customized services.

2. Fifteen years of steel export experience, with own agents in Bangladesh, Turkey, Cameroon and other countries;

3. Product quality is guaranteed, and the ship plates are certified by nine major classification societies. Various testing and services can be provided, and third-party testing is accepted;

4. Professional after-sales service team to provide various services to our customers.

Get Price And Support

Simply complete the form below, click submit, you will get the price list and our representative will contact you within one business day. Please also feel free to contact us by email or phone. ( * Denotes a required field).